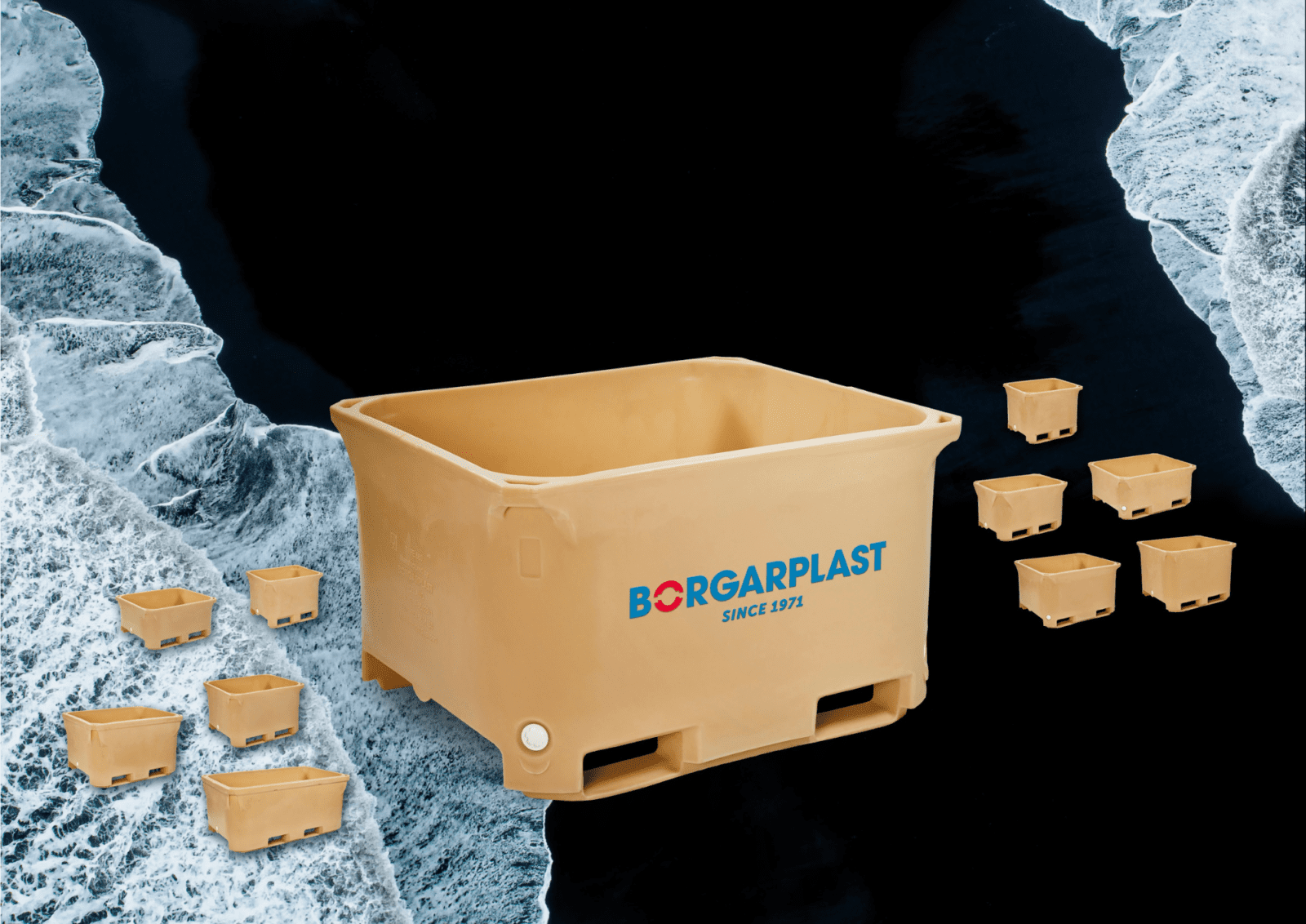

In 1983 we launched the first version of fish tubs. These tubs did not have any insulation but in 1986 we launched version 2.0 and this time with insulation. The original design had three skids on the tubs, one each side and one in the middle. Our clients who were working in the Icelandic fishery industry did not want the middle skid on the tubs.

The reason was mostly twofold. On one hand the middle skid used to break frequently due to collisions from forklifts. On the other hand, dirt and debris fell off the middle skid and into the tub below when being stacked.

With the wishes of our clients in mind we started to work on the design with only 2 skids.

The middle skid had provided strength for the bottom of the tub so that problem had to be solved. How could we make sure the bottom did not break when full of fish or other food product. The solution is in the convex bottom design. The way the bottom is shaped slightly upwards in the middle distributes weight to the four corners and therefore protecting the middle of the tub where there is no skid.

But that’s not all. There is more material in the middle of the tub due to the design and we also added a riffled surface on the outer part of the bottom. This way we could put in even more material and provide protection from forklift damage.

The convex bottom design is not just for extra strength. The design makes it easier to empty and clean the tubs between loads as all liquid flows to the corners and to the drainage holes.

The convex bottom design is just one of many features that make up the reason why Borgarplast insulated fish containers are widely considered the best in the world. We will let our clients be the judge of that, but we can say for sure that great thought has been put into the design to make them easier to use and stronger.